Mechanical assembly is a crucial process in the manufacturing industry that involves the construction of various mechanical parts to create functional systems and products. In India, one prominent player in the field of mechanical assembly is Deccan Engineering Works. With their expertise and commitment to quality, Deccan Engineering Works has earned a reputation for delivering efficient and precise mechanical assembly solutions. In this article, we will delve into the details of mechanical assembly in India, explore the significance of mechanical parts assembly, and highlight the capabilities of Deccan Engineering Works as a leading brand in the industry.

Mechanical assembly in India refers to the process of assembling individual mechanical parts to create complex systems and machinery. It involves meticulous attention to detail, precision, and adherence to engineering standards. Mechanical assembly encompasses a wide range of industries, including automotive, aerospace, electronics, and heavy machinery. In India, the mechanical assembly sector has experienced significant growth due to the country's skilled workforce, cost-effective manufacturing capabilities, and advanced infrastructure. Indian manufacturers like Deccan Engineering Works have emerged as key players in providing high-quality mechanical assembly services to both domestic and international clients.

Mechanical parts assembly plays a vital role in the manufacturing process as it ensures the seamless integration of various components into a functioning unit. The process involves connecting, fastening, and aligning different parts to create a reliable and efficient system. With the advancement in technology and automation, mechanical parts assembly has become more sophisticated, enabling higher precision and quicker production cycles. Deccan Engineering Works specializes in mechanical parts assembly and excels in meeting the diverse needs of their clients. Their team of skilled technicians and engineers possesses in-depth knowledge of assembly techniques, ensuring that every component fits together perfectly. From small-scale assemblies to large and complex systems, Deccan Engineering Works leverages their expertise to deliver top-notch assembly solutions.

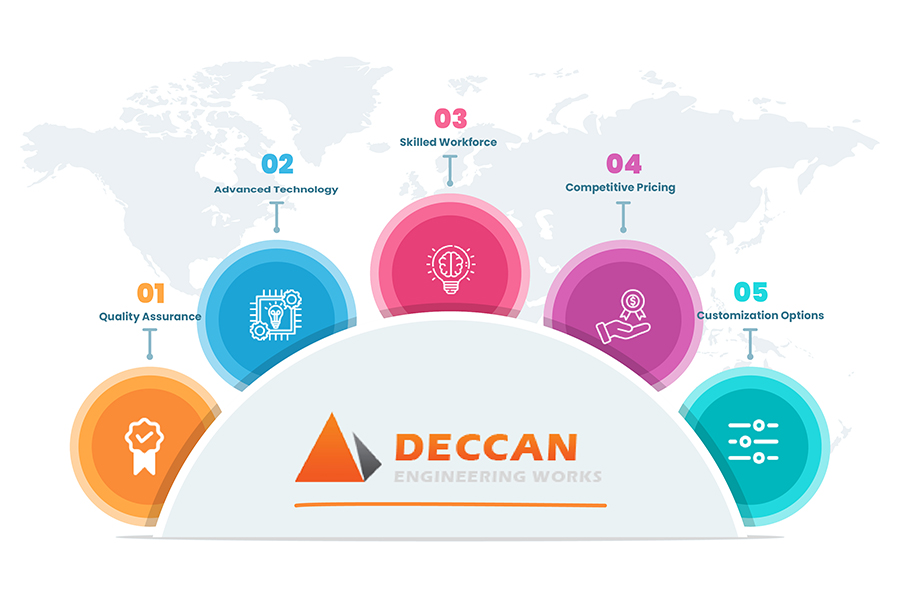

Deccan Engineering Works stands as a leading brand in mechanical assembly, offering comprehensive solutions to clients across various industries. With decades of experience and a commitment to excellence, they have established themselves as a reliable partner for mechanical assembly projects. Here are some key features that make Deccan Engineering Works a preferred choice for businesses seeking mechanical assembly services:

Deccan Engineering Works boasts state-of-the-art infrastructure, equipped with advanced machinery, tools, and equipment necessary for efficient mechanical assembly. They leverage the latest technologies to enhance productivity, precision, and quality control throughout the assembly process.

The success of any mechanical assembly project heavily relies on the expertise of the workforce involved. Deccan Engineering Works takes pride in its highly skilled team of technicians, engineers, and assembly specialists. Their knowledge and experience enable them to tackle complex assembly challenges while adhering to stringent quality standards.

The success of any mechanical assembly project heavily relies on the expertise of the workforce involved. Deccan Engineering Works takes pride in its highly skilled team of technicians, engineers, and assembly specialists. Their knowledge and experience enable them to tackle complex assembly challenges while adhering to stringent quality standards.

Deccan Engineering Works understands that each client has unique requirements. They offer customization and flexibility in their mechanical assembly services, ensuring that the final product aligns perfectly with the client's specifications. Whether it's a one-time project or a long-term partnership, Deccan Engineering Works strives to provide tailored solutions that meet the individual needs of their clients.

A: Mechanical assembly services cater to a wide range of industries, including automotive, aerospace, electronics, consumer goods, medical devices, and heavy machinery. These industries rely on mechanical assembly to bring together various components and systems, ensuring the smooth functioning of their products.

A: Deccan Engineering Works follows a stringent quality control process throughout the mechanical assembly process. They conduct rigorous inspections at every stage, using advanced testing equipment and techniques. Additionally, they adhere to international quality standards and have implemented robust quality management systems to ensure that the final product meets or exceeds customer expectations.

A: Yes, Deccan Engineering Works has the capabilities to handle mechanical assembly projects of various sizes. They have experience in assembling small, intricate components as well as large and complex systems. Their skilled workforce, coupled with their cutting-edge infrastructure, enables them to efficiently handle projects of different scales.

Mechanical assembly in India is a vital component of the manufacturing industry, and Deccan Engineering Works stands at the forefront, delivering exceptional assembly services. With their commitment to quality, skilled workforce, and advanced infrastructure, they continue to set the standard in mechanical assembly. Whether it's automotive, aerospace, or any other industry, Deccan Engineering Works ensures seamless integration and precision, contributing to the overall success of their clients' products.

Deccan Engineering Works design and build custom Mechanical parts assembly for a wide range of products in various industries. Our engineers have the experience and creative ability to invent new concepts and redesign existing assemblies to make our costumer’s products possible and profitable. All of our high precision machining is done with strict quality control.

Leveraging our years of experience in this domain, we are engaged in providing an enormous quality range of Mechanical parts assembly to our customers. This Assembly Machine is used for the automation of manufacturing process. Besides, we thoroughly test these products for quality before making final delivery.

We adhere to stringent quality control measures throughout the manufacturing process to ensure that our machined parts and components meet the highest quality standards. Our team of experienced engineers and inspectors conducts rigorous inspections and tests to guarantee the reliability and performance of our products.

Equipped with advanced CNC machines, computer-aided design (CAD) software, and other cutting-edge tools, we have the capability to handle complex machining requirements. Our commitment to technological advancement enables us to stay ahead of the curve and provide innovative solutions to our clients.

At Deccan Engineering Works, we have a team of highly skilled and experienced professionals who are passionate about their craft. Our engineers and technicians possess in-depth knowledge of machining techniques and are dedicated to delivering excellence in every project.

We believe in offering competitive pricing without compromising on the quality of our products. Our efficient production processes, streamlined operations, and strategic partnerships enable us to provide cost-effective solutions that add value to your business.

We understand that every customer has unique requirements.That's why we offer tailored solutions and customization options meet your specific needs. Whether it's a one-off prototype or large-scale production run,we work closely with our clients to provide personalized services and deliver superior results.