Bucket Elevators

A bucket elevator is a crucial piece of equipment used in various industries for the vertical transportation of bulk materials. Here are the key points regarding its importance and principles:

Importance of Bucket Elevators

1. Efficient Material Handling: Bucket elevators are designed to move materials vertically, which is essential in maximizing space and improving operational efficiency in warehouses, factories, and processing plants.

2. Versatile Applications: They can handle a wide range of materials, including grains, powders, pellets, and other bulk products, making them suitable for various industries such as agriculture, mining, and food processing.

3. Reduced Labour Costs: Automation of material handling through bucket elevators reduces the need for manual labour, thereby lowering labour costs and minimizing human error.

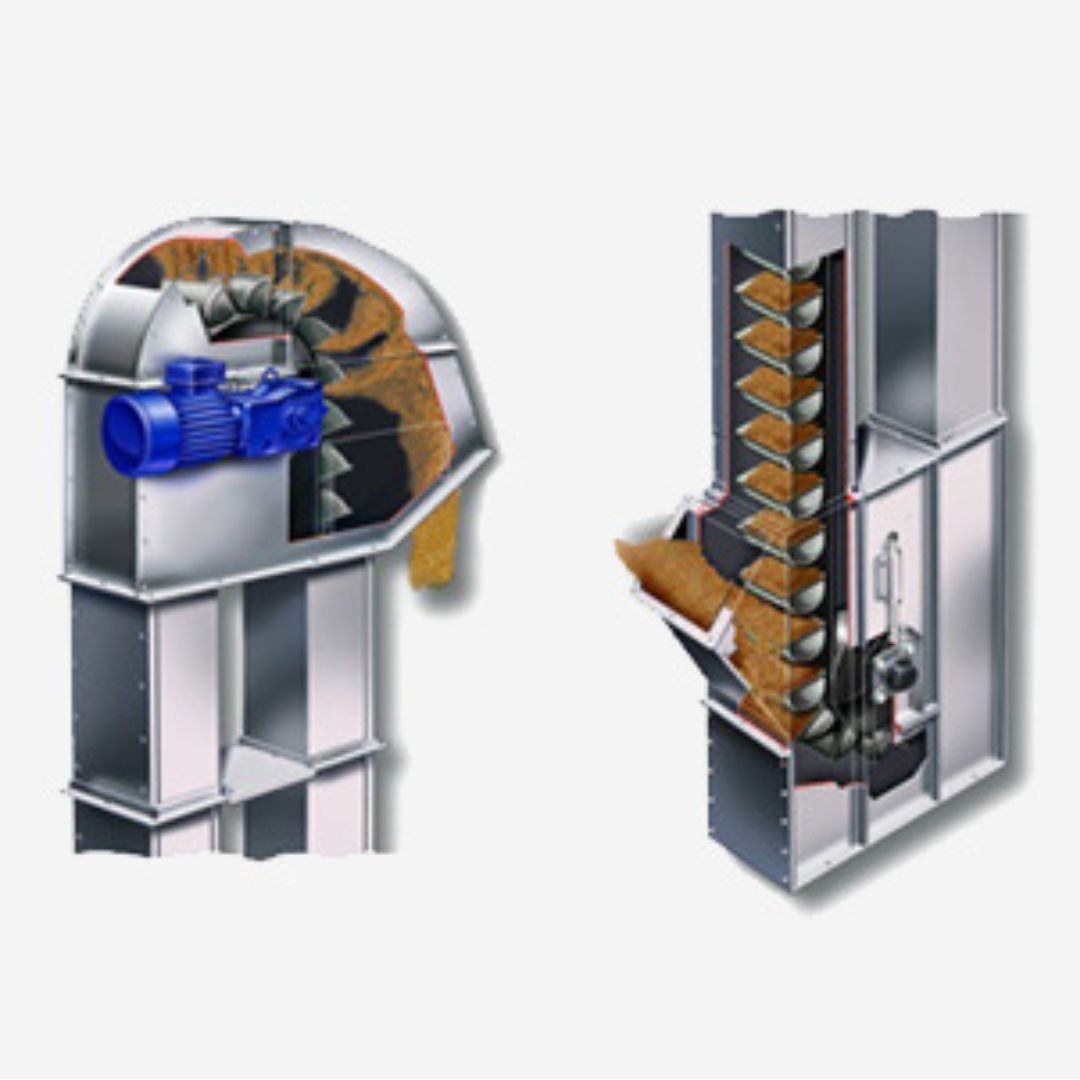

Bucket elevators have 3 variants

- Belt type

- Chain type &

- Z type

Buckets are made of metal & polymers both depending upon its capacity pattern of Bucket elevator is selected.

Z-Type Bucket Elevators

Z-type bucket elevators are important for their space-saving design and efficiency in handling various materials. Their operational principles focus on a unique Z-shaped pathway that facilitates both vertical and horizontal movement, providing a streamlined solution for material transport.

Key Requirements for Building a Bucket Elevator

Bucket elevators are essential for efficiently transporting bulk materials vertically in industries such as agriculture, mining, and manufacturing.

They are designed with buckets attached to a belt or chain, which moves the material smoothly between different heights.

- Buckets

- Belt or Chain

- Drive System

- Maintenance Access

- Casing/Enclosure

- Inlet and Outlet Sections

- Control System

- Supporting Structure

- Material Compatibility

- Head and Tail Pulleys/Sprockets

Latest News.

Get the latest update, trips & tricks from our expert.