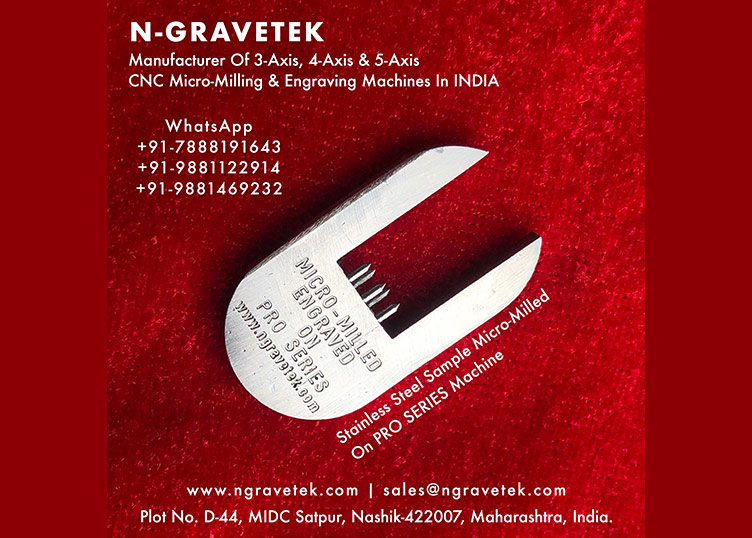

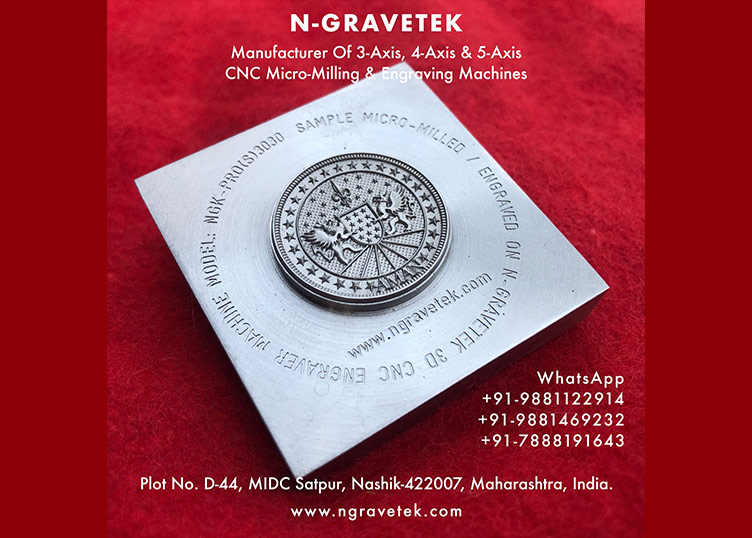

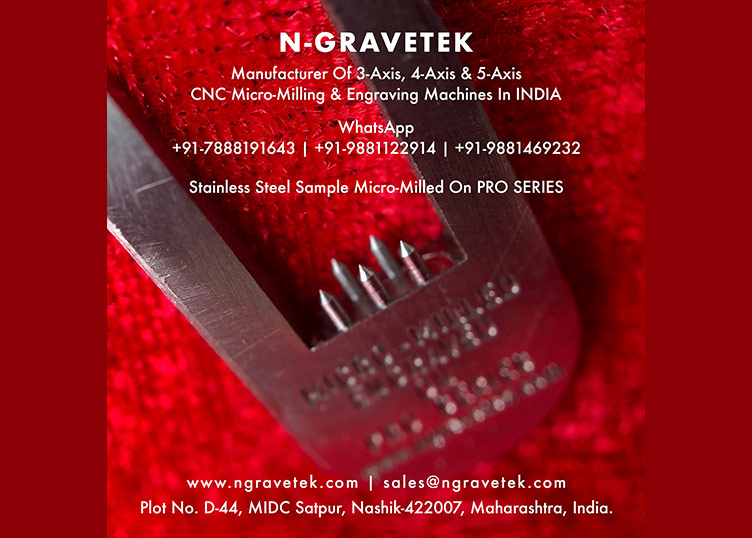

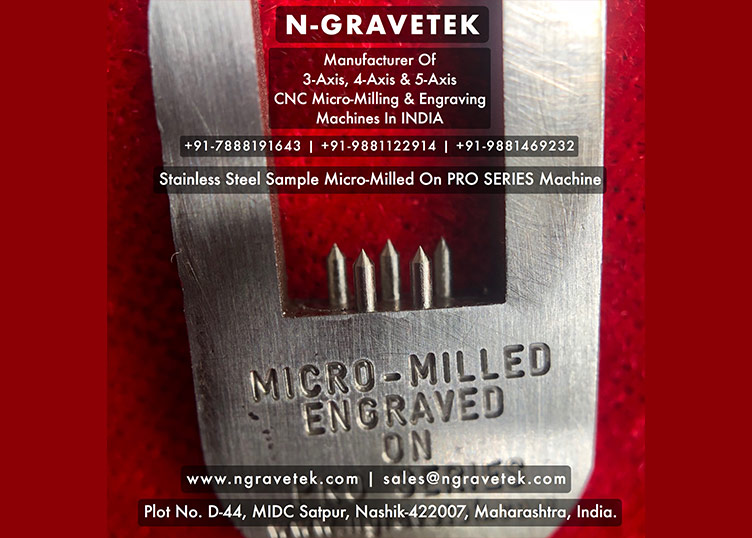

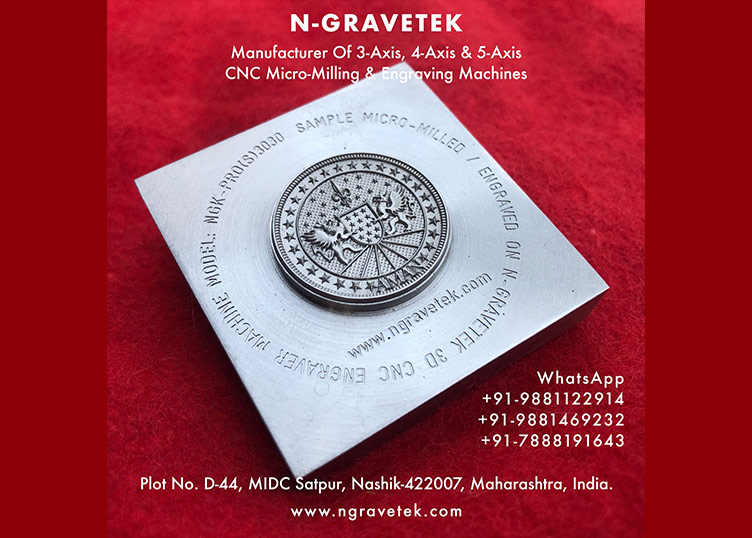

PRO Series

Ball Screw

LM Guide

Telescopic Guards

Proximity Sensor

PRO SERIES Machine Highlights

- Time Proven, Sturdy and Versatile Full Digital CNC Precision Micro-Milling/Engraving Machine.

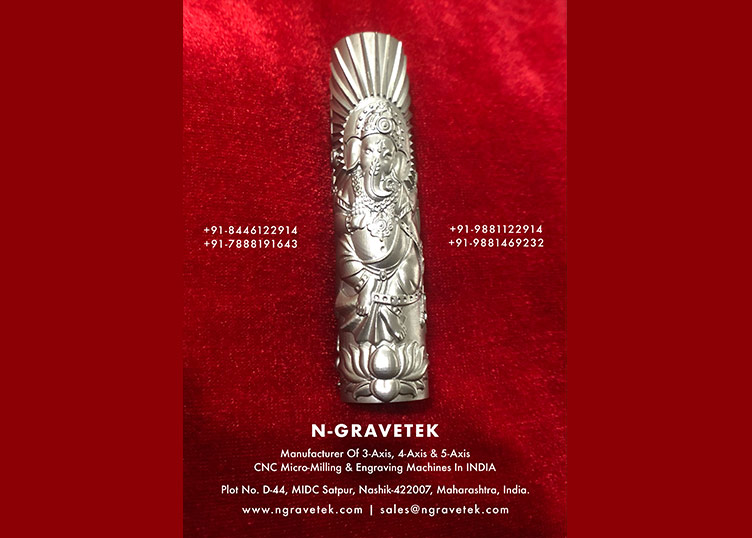

- Machine future ready for 4th axis for doing Micro-Milling & Engraving operations on cylindrical work piece.

- Most economical yet powerful CNC engraving machine in our product line.

- AC servo motor & drive for all 3-axis.

- On power failure, machine resumes from same point where it stopped.

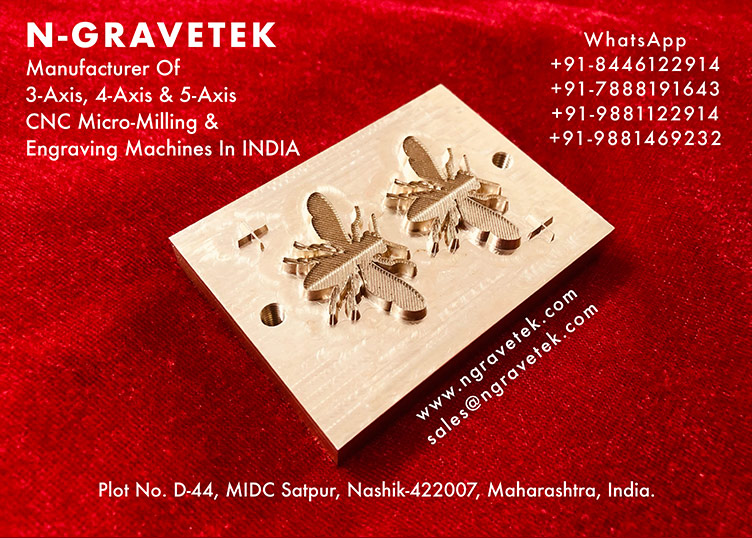

- Specially designed for Micro-Milling & Engraving operations.

- Cast iron foundry body with virtually no vibrations which gives better surface finish & better tool life.

- Closed loop control system with possibility to save 6 work origins.

- Standalone machine with USB compatibility. Not necessary to connect with PC.

- DSP based programmable multi-axis simultaneous 3-axis controller which uses standard G-code NC file type input. Ball screw with LM guide-ways enable higher rapids and better productivity.

- Easy to operate using simple & user friendly handheld keypad.

- Compatible with broad range of CAM software.

- Brake Motor used for dynamic balancing of Z. Axis

Machine Technical Specifications

| Description | NGK-PRO (S) 3030 | NGK-PRO (S) 4040 | NGK-PRO (S) 6040 |

|---|---|---|---|

| Working Area (X) x (M) x (Z) | 300 x 300 x 150 | 400 x 400 x 150 | 600 x 400 x 150 |

| Total Size- Clamping Area in mm | 350(X) x 375(Y)) | 450(X) x 475(Y) | 650(X) x 475(Y) |

| T-Slot Size | M10 | ||

| T-Slot Centre Distance | 104mm | 138mm | 103mm |

| Engraving Speed | 3000 mm/min | ||

| Rapid Speed | 5000 mm/min | ||

| Spindle Speed | 24000 RPM | ||

| Spindle Power | 2.2 KW | ||

| Maximum Tool Diameter | 10 mm | ||

| Guide System | Precision Linear motion Guide | ||

| Drive System | Precision Ball Screw | ||

| Motor/Drive | SERVO | ||

| Standalone Controller | (DSP) Digital Signal Processor | ||

| Internal Memory | 128MB | ||

| Expandable | 8GB | ||

| USB Connectivity | YES | ||

| Machine Self Zero | YES | ||

| User Work Zero (G54) | 6 | ||

| Auto Spindle On/Off | YES | ||

| Auto Coolant On/Off | YES | ||

| Break Point Resume | YES | ||

| Resume After Tool Breakage | YES | ||

| Power Resume Function | YES | ||

| NC File Format | ISO G-Code (Standard) | ||

| Accuracy | 0.008mm | ||

| Repeatability | 0.010mm | ||

| Feeding Height | 200 MM (Customisable) | ||

| Safe Weight on Table | 150 Kg | 175 Kg | 200 Kg |

| Weight of Machine | 700 Kg | 800 Kg | 950 Kg |

| Floor Space (mm)- (L) x (D) x (H) | 700 X 700 X 2000 | 1000 X 1000 X 2000 | 1200 X 1000 X 2000 |

| Operating Tempreture | 5 to 35 Degrees | ||

Standard Accessories

| Names | Nos |

|---|---|

| Engraving Tools | 5 Nos |

| Clamping Set | 4 Nos |

| Spanner (Required Sizes Only)) | 3 Nos |

| Collets (6mm & 3mm) (Single Each) | 2 Nos |

| Allen Keys (Required Sizes Only) | 5 Nos |

| Coolant System | 1 Nos |

Upgraded Accessories

- PC Based Controller

- Suitable PC Required For PC Based Controller Integrated

- System Embedded

Optional Accessories

- Z-Calibrator (Auto Z)

- 4' Milling Vice

- 2" (Width 3" (Openning) Precision Grounded Vice

- Rotary Axis 4th Axis

- Tool Grinder (Taiwan Make)

- (Training Included Our Works)

FILL IN YOUR DETAILS TO

SCHEDULE LIVE DEMO

We Are Always Best For Industrial Solution

- Think Positive, Think Always

- Everyone Loves Got An Incredible

- Our Professional Team Works

- We Are Laregest Independent