Liquid Ejectors

Liquid Ejectors are simple devices that operate on the basis of the jet Venturi principle.

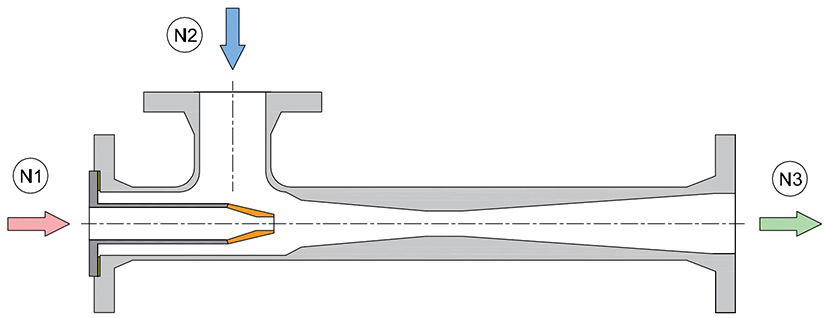

Liquid Ejectors typically have 3 connections

- 1. High Pressure(HP) Liquid Inlet

- 2. Suction

- 3. Outlet

During operation Liquid Ejectors are able to create a pressure differential across its Suction and outlet. Liquid Ejectors utilize the energy in pumped liquid entering from the HP liquid inlet to create this pressure differential.

This enables Liquid Ejectors to be used for creating vacuum / low pressure at its suction. The low pressure allows the Liquid Ejectors to suck liquids through the suction. The suction liquid mixers with the HP liquid inside the Ejector and gets pumped out from the Outlet. The discharge contains the mixture of HP liquid and suction liquid.

This phenomenon allows the Liquid Ejectors to be used for sucking and pumping Water, chemicals, acids, alkalis, slurries, sludges, etc

The amount of suction liquid sucked and the head difference between Suction and Outlet depends upon the size of the Liquid Ejector and the internal construction. Further the operating flows can be controlled by regulating the HP Liquid, Suction & Outlet Pressures.

Typical Applications

- Chemical Dosing

- Pit Draining

- Slurry Pumping

- Sludge Pumping

- Ballast water pumping

Features of Liquid Ejectors

- Custom designed models – ensures perfect fit for your application.

- Self Priming mode of operation

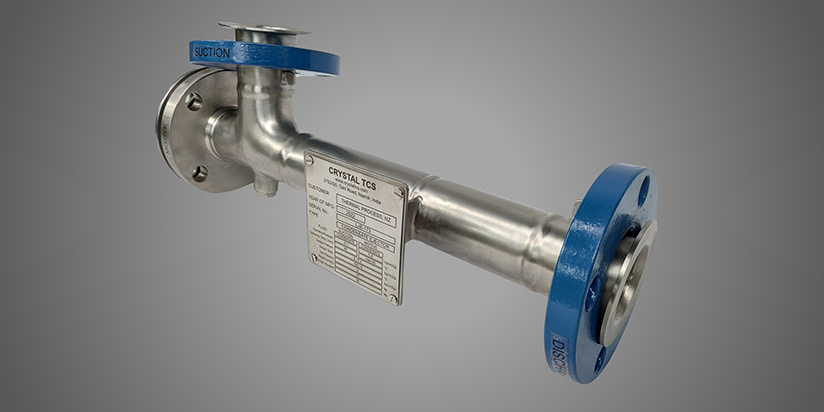

- Availability in multiple type of end connections – Flanged, Threaded

- Available in a large variety of materials

| Metallic | Non Metallic |

|---|---|

| Carbon Steel | PP (Poly-propylene) |

| Stainless Steels SS 304 / SS 316 | PTFE (Poly-tetra-fluoro-ethylene) |

| Duplex & Super Duplex Stainless Steel | |

| Exotic metals (Hastelloy, Inconel, Titanium) |

Benefits of Liquid Ejectors

- Static Device without any moving parts – ensure long reliability and maintenance free operation.

- Tolerate entry of solids particles into the ejector – avoids abrupt breakdowns.

- Small & compact size – allows installation in tight spaces & difficult to access areas.

- Silent Operation

- Non sparking operation – can be safely used in hazardous & flammable areas

- Manufactured in multiple materials – allows using the most cost-effective & chemically compliant materials for the application.