Applications in Power Generation

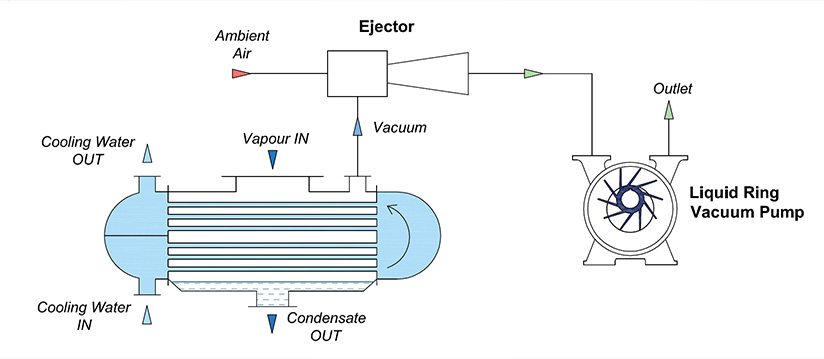

Atmospheric Air Ejectors / Liquid Ring pump Ejectors for Condensor Vacuum

The required vacuum in the condenser is equivalent to the saturation pressure of the condensate and varies between 55~80 mbar depending upon the geographical region. The max vacuum created by the Liquid Ring Vacuum Pump is limited by its sealing water temperature.

In such cases an air ejector is mounted on the Liquid Ring Vacuum Pump to boost its vacuum. This air ejector uses air from the atmosphere as the energy input and hence is known as Atmospheric Air Ejector. (Read more)

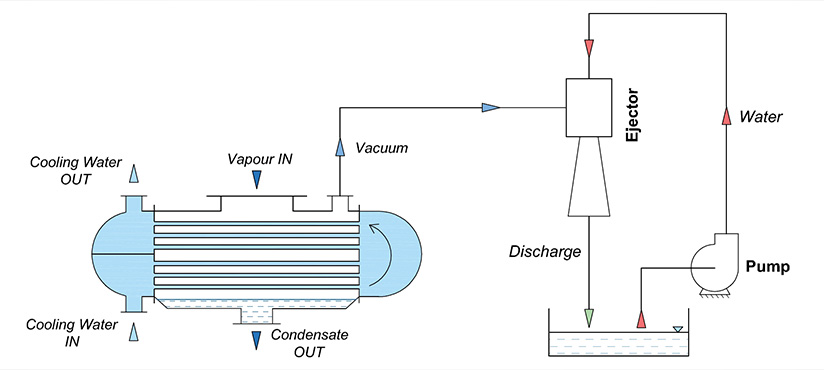

Liquid jet Vacuum Ejectors for Condensor Evacuation

The condensors used in Thermal Powerplants are considerable in size and have large internal volumes. During start-up, the condenser pressure has to be first lowered before starting the turbines. Due to the large internal volume the primary vacuum system takes a lot of time for attaining the required vacuum.

Water Eductors are secondary vacuum source and are used only during start-up. Service Water at 2.5~7 bar(a) is a commonly available utility and (Read more)

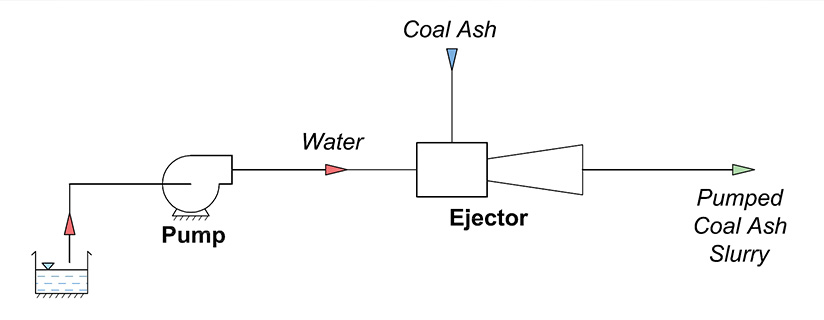

Slurry Ejectors for transporting Coal Ash.

Slurry Ejectors are essentially liquid ejectors that utilize pumped water for operation. Slurry Ejectors suck the Coal Ash from the collection point and mix it with water inside the ejector. The mixture of Coal Ash and Water is then pumped out from the Ejector outlet.

Thus the Slurry Ejector also acts as pump and can develop significant head at the outlet This enables the Coal Ash slurry to be pumped to long distances with help of the Slurry Ejector. (Read more)