Applications in Oil and Gas Refining

Gas Ejectors for Flare Gas Recovery

Flare gases are a combination of raw natural gas, vapours generated from crude oil tanks and other gas generated during oil & gas production and refining. Traditionally these gases were typically burnt in flare stacks.

But in the past decade Oil & gas producers and Refiners have begin to realise the disadvantages of burning flare gas. The disadvantages being (Read more)

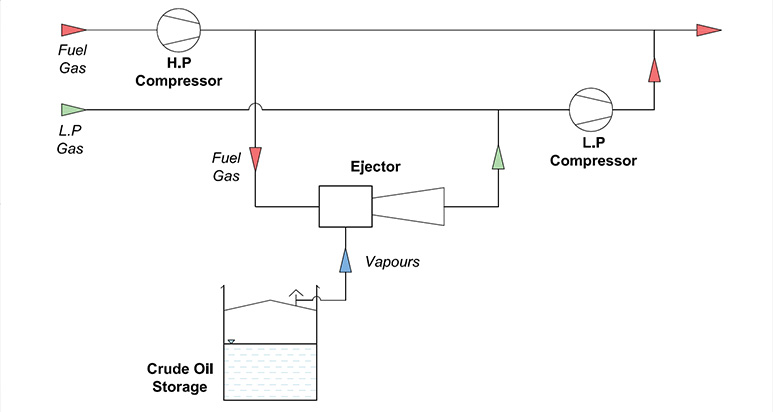

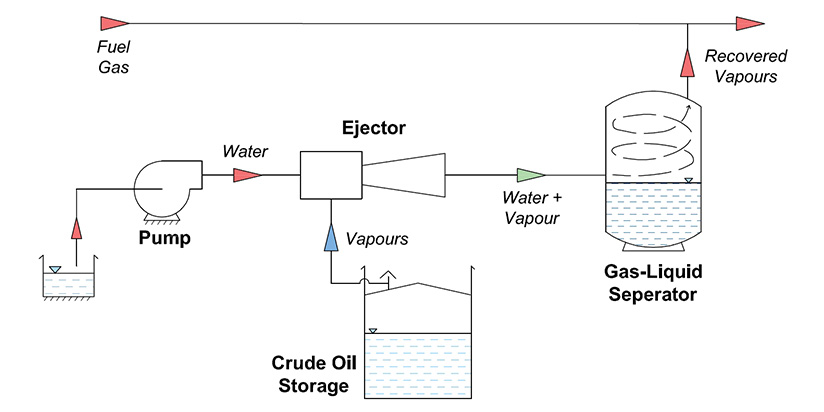

Gas Ejectors for Vapour Recovery from Crude Oil Tanks

Oil Production sites and Refineries use large tanks for storing Crude Oil. Crude Oil is a mixture of various hydrocarbons. When stored in a tank, the lighter fractions in the crude mostly Methane and Ethane flash off from the crude oil. These Methane & Ethane in vapour form occupy the space between the floating roof and the Tank liquid level.

The vapours are flashed continuously and keep on the collecting over the liquid level. (Read more)

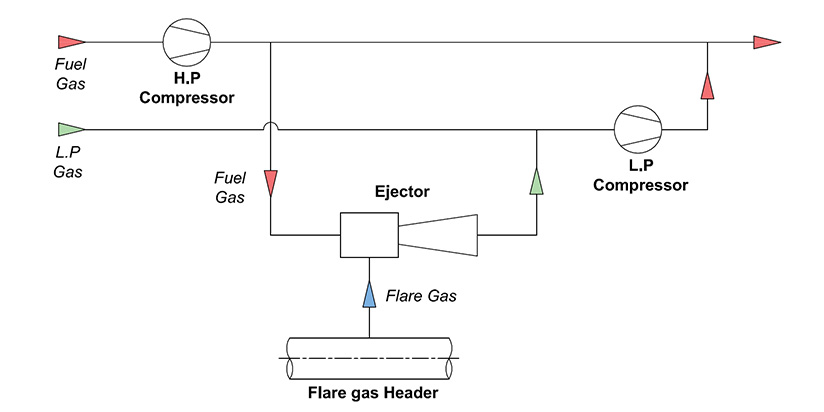

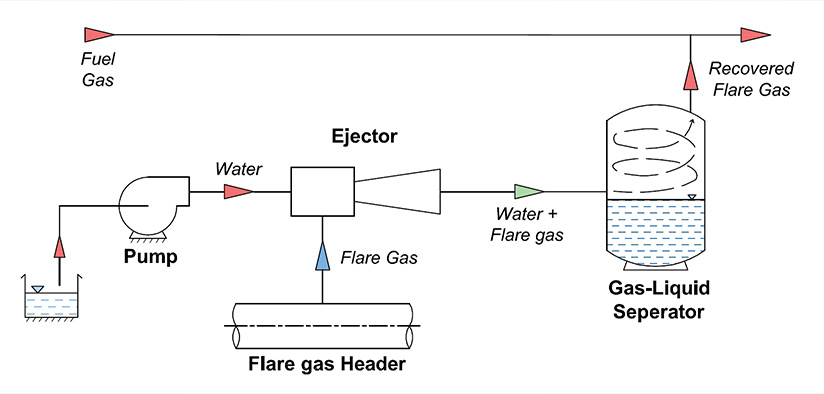

Liquid jet Gas Compressors for Flare Gas Recovery

Flare gases are a combination of raw natural gas, vapours generated from crude oil tanks and other gas generated during oil & gas production and refining. Traditionally these gases were typically burnt in flare stacks. But in the past decade Oil & gas producers and Refiners have begin to realise the disadvantages of burning flare gas. The disadvantages being (Read more)

Liquid jet Gas Compressors for Vapour Recovery from Crude Oil Tanks

Oil Production sites and Refineries use large tanks for storing Crude Oil. Crude Oil is a mixture of various hydrocarbons. When stored in a tank, the lighter fractions in the crude mostly Methane and Ethane flash off from the crude oil. These Methane & Ethane in vapour form occupy the space between the floating roof and the Tank liquid level.

The vapours are flashed continuously and keep on the collecting over the liquid level. (Read more)

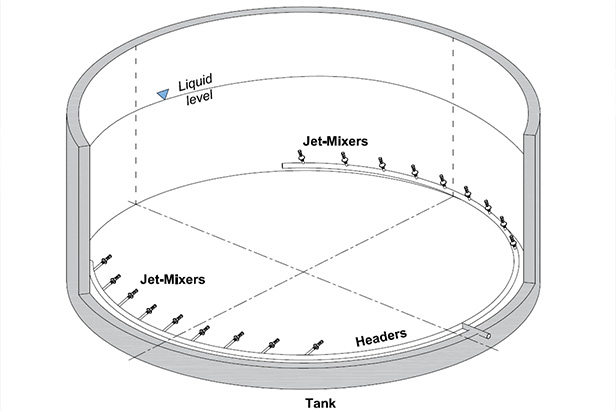

Jet Mixers for Mixing & Agitation of Crude Oil Storage Tanks

Raw Crude Oil is collected in large storage tanks after extraction from production sites. Raw Crude contains multiple impurities such as tar, sand, water and coke. If kept idle the impurities tend to settle and water accumulates in some pockets at the bottom of the tank. This mixture is referred to as Bottom Sludge & Water (BS&W). (Read more)

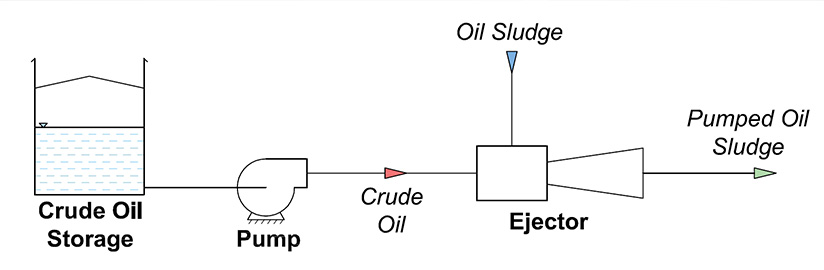

Sludge Eductors for transporting Oil Sludge

Large Storage tanks are used in Oil & Gas Production facilities to store the extracted Crude Oil while Petroleum refineries use them to store finished petroleum products (Diesel, heavy oils, etc)

When Crude Oil or Petroleum products lie idle in the storage tank, it leads to formation of oil sludge inside the tank. The Oil sludge deposits at the bottom of the tank. This oil sludge deposition is problematic as increases corrosion risk and also reduces the storage capacity. (Read more)