Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

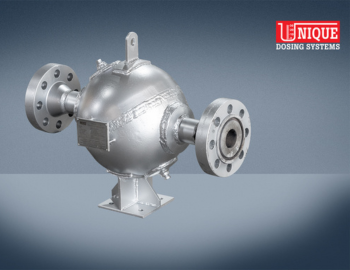

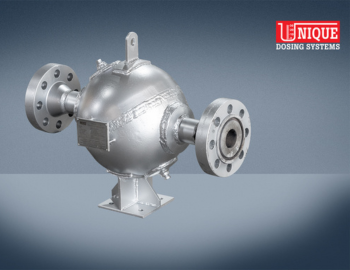

A pulsation dampener is a container with gas inside, normally dry nitrogen.

In every pulsation dampener there is a separator element between the gas it is charged with and the liquid of the circuit; its basic function being to avoid the leaking of the gas into the circuit. This separator element is basically made of two kinds of materials: Rubber (NBR, EPDM, FPM, butyl, silicone, etc…) or a thermoplastic material (normally PTFE); although it can also be made in stainless steel

When a rubber separator element is used, the dampener is called bladder type. If the material is PTFE, we refer to membrane type and bellows type dampeners, depending on the shape of the separator element.

The bellows can also be made of stainless steel, to suit special dampeners designed for working with high temperature liquids.

Choosing between different types of dampener depends on characteristics of the circuit like working pressure, temperature and chemical compatibility between the liquid and the material of the separator.

All our pulsation dampeners are made according to the ASME VIII Div.1 & 8 codes requirements.

We can supply all of our dampeners with different circuit connection gauges as well as fitted with whatever flange, either screwed on, welded or integrated, to suit the customer’s needs.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters