Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

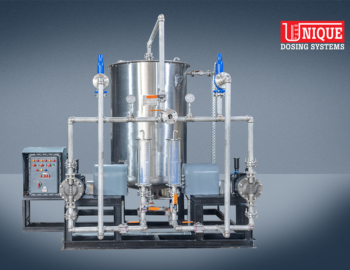

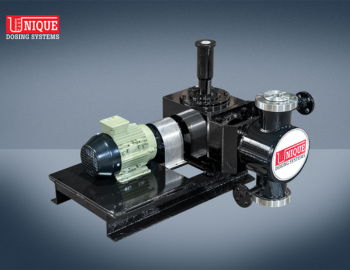

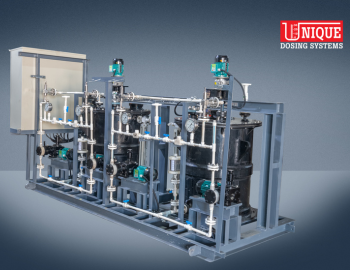

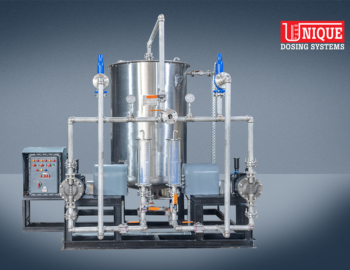

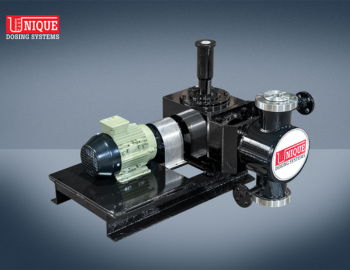

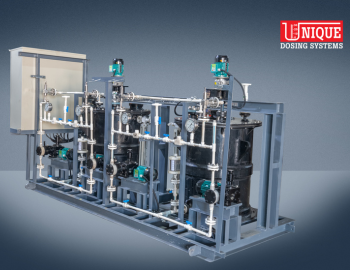

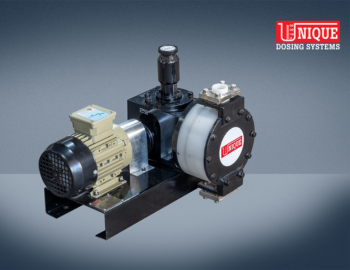

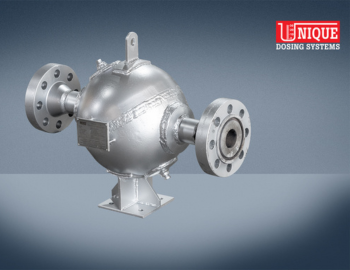

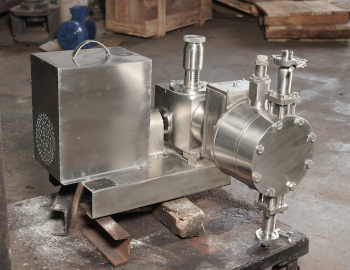

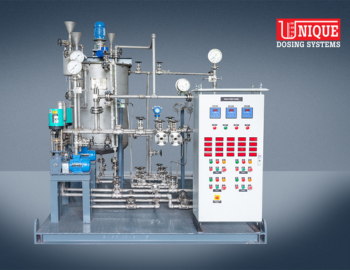

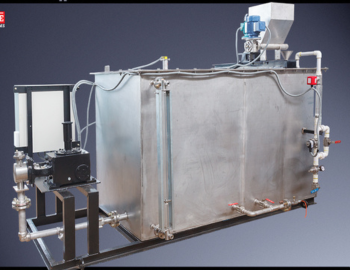

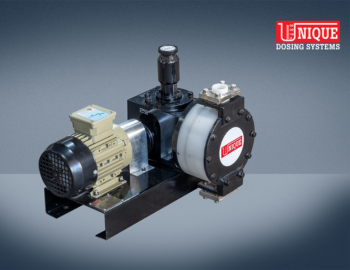

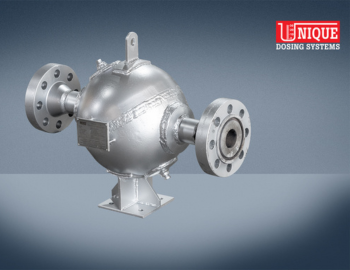

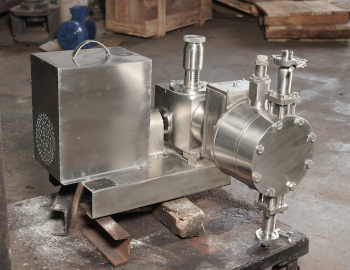

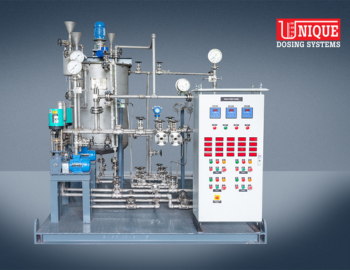

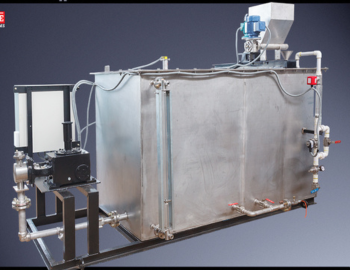

Achieve unparalleled accuracy and efficiency in your distillery operations with the Tro Dosing Pump. Designed for the unique dosing needs of the distillation industry, our pumps ensure precise ingredient measurement and seamless integration into your production process.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters

With advanced dosing technology, Tro Dosing Pump optimizes production by minimizing waste and maximizing product consistency. Whether you are producing whiskey, vodka, rum, gin, or other spirits, our dosing pumps provide the control and precision needed for superior quality.