Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

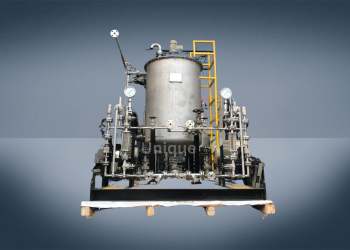

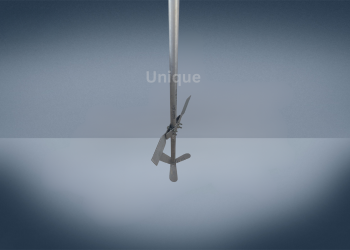

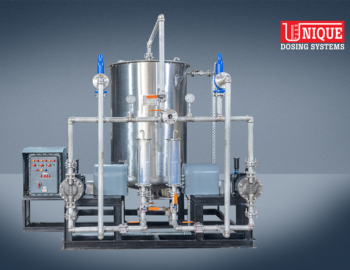

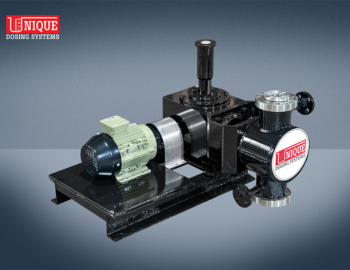

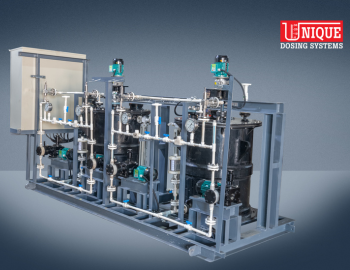

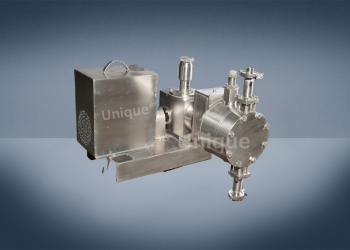

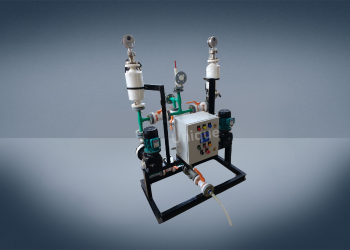

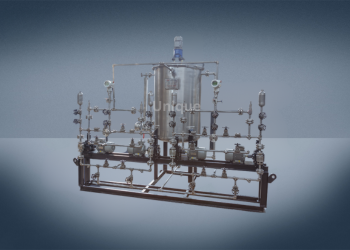

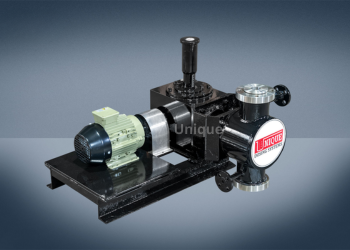

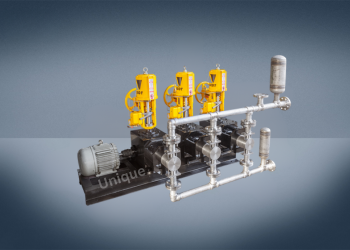

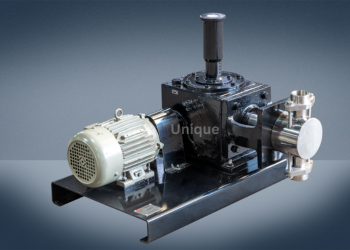

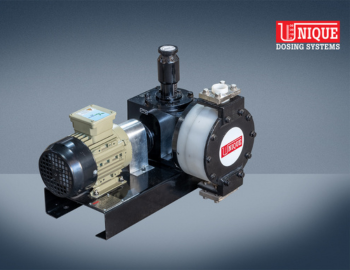

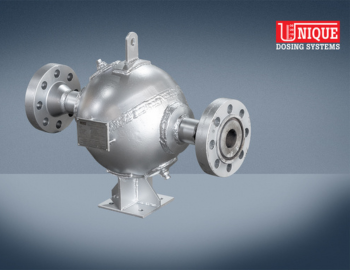

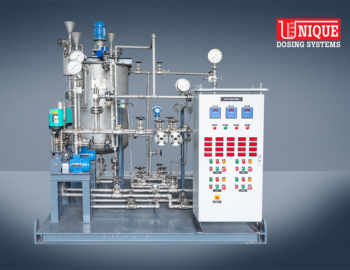

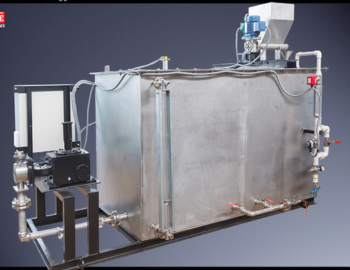

Unique dosing system, Nasik( Maharashtra, India) is a Alum Dosing Pump Manufacturers that are extensively used in different water treatment factory and paper assiduity. The capacity of Alum Dosing Pumpranges from0 LPH to 1150 LPH. Alum Dosing Pump is a mechanical actuated diaphragm pump and used for low capacity and low pressure. Diaphragm is PTFE carpeted and supported by sword core and temperature resistance material. Alum Dosing Pumps are suitable for Water treatment factory, Chemical and Paper diligence.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters