Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

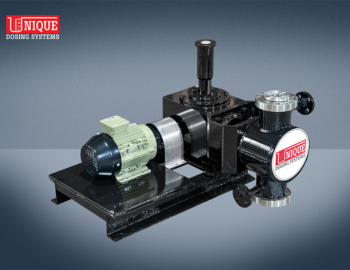

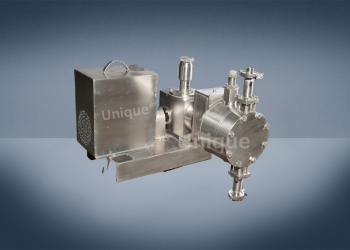

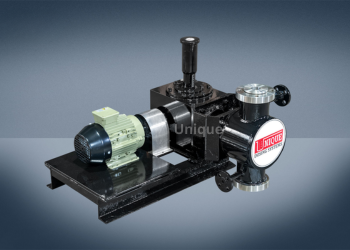

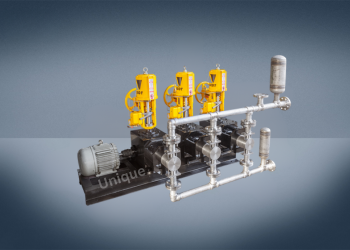

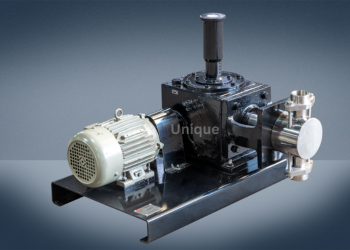

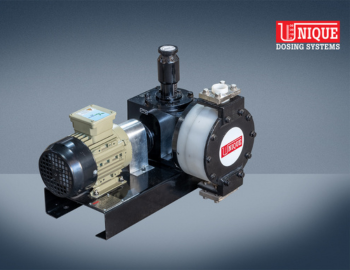

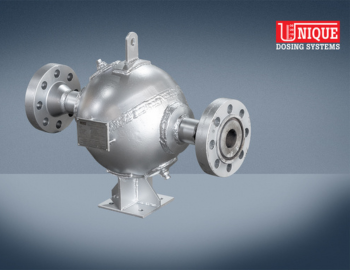

We are proud to introduce ourselves as one of the leading manufacturers of Shrikhand Transfer Pumps required to transfer Shrikhand from one place to another. These pumps can hold ointment, ice, Shrikhand, ghee, milk, paste etc. Can be used for.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters