Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

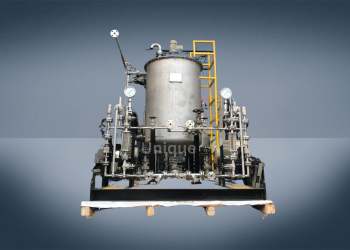

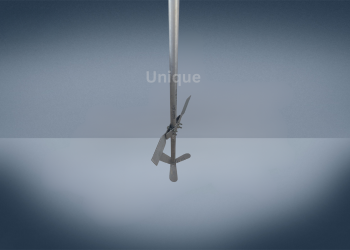

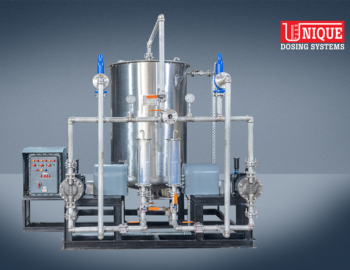

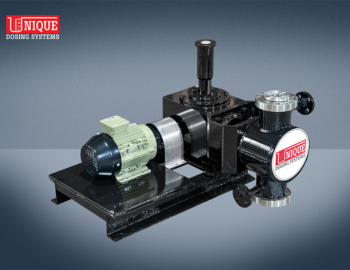

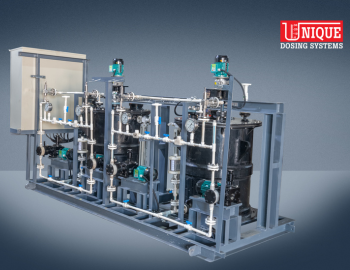

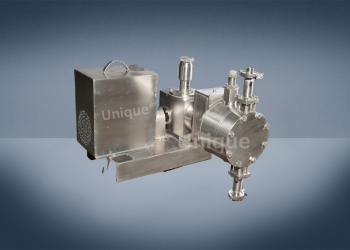

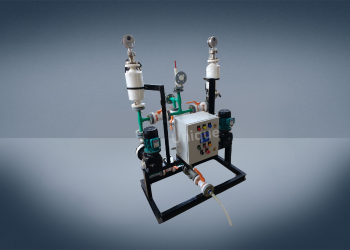

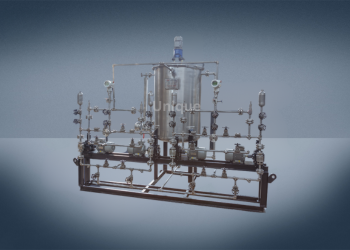

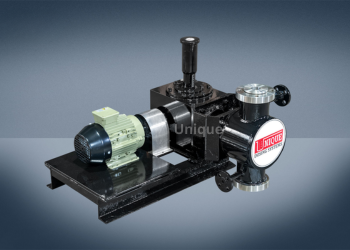

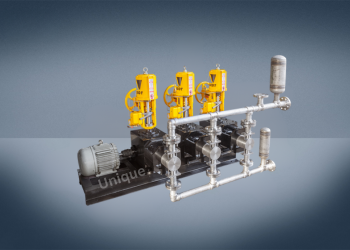

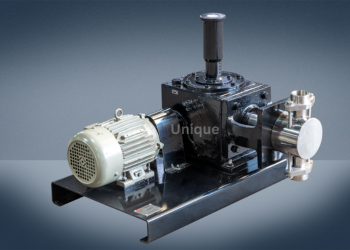

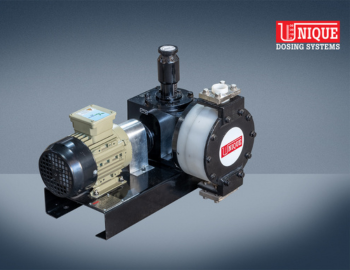

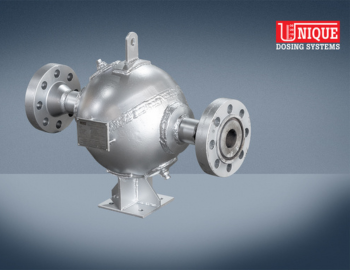

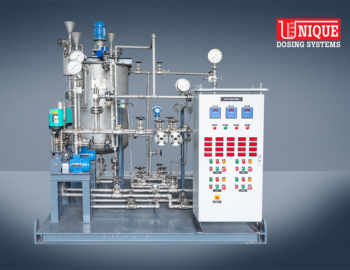

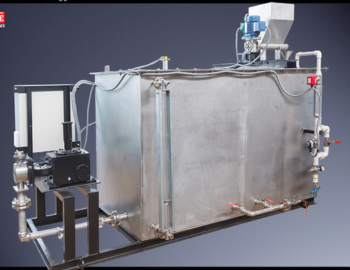

Sugar Industry Pumps manufacturers offer different products and are widely used in the sugar industry. It is ergonomically designed to provide highly stable, continuous, uninterrupted, smooth and low-vibration access in amounts proportional to rotational speed. Designed with the solid guidance of quality management knowledge, these products are directly connected to rectangular shaped and conical feed hoppers via flange drives to ensure flawless operation. , Sugar Industry Pumps manufacturers, Sugar Industry Pumps Suppliers and Exporters in Nashik, India

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters