Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

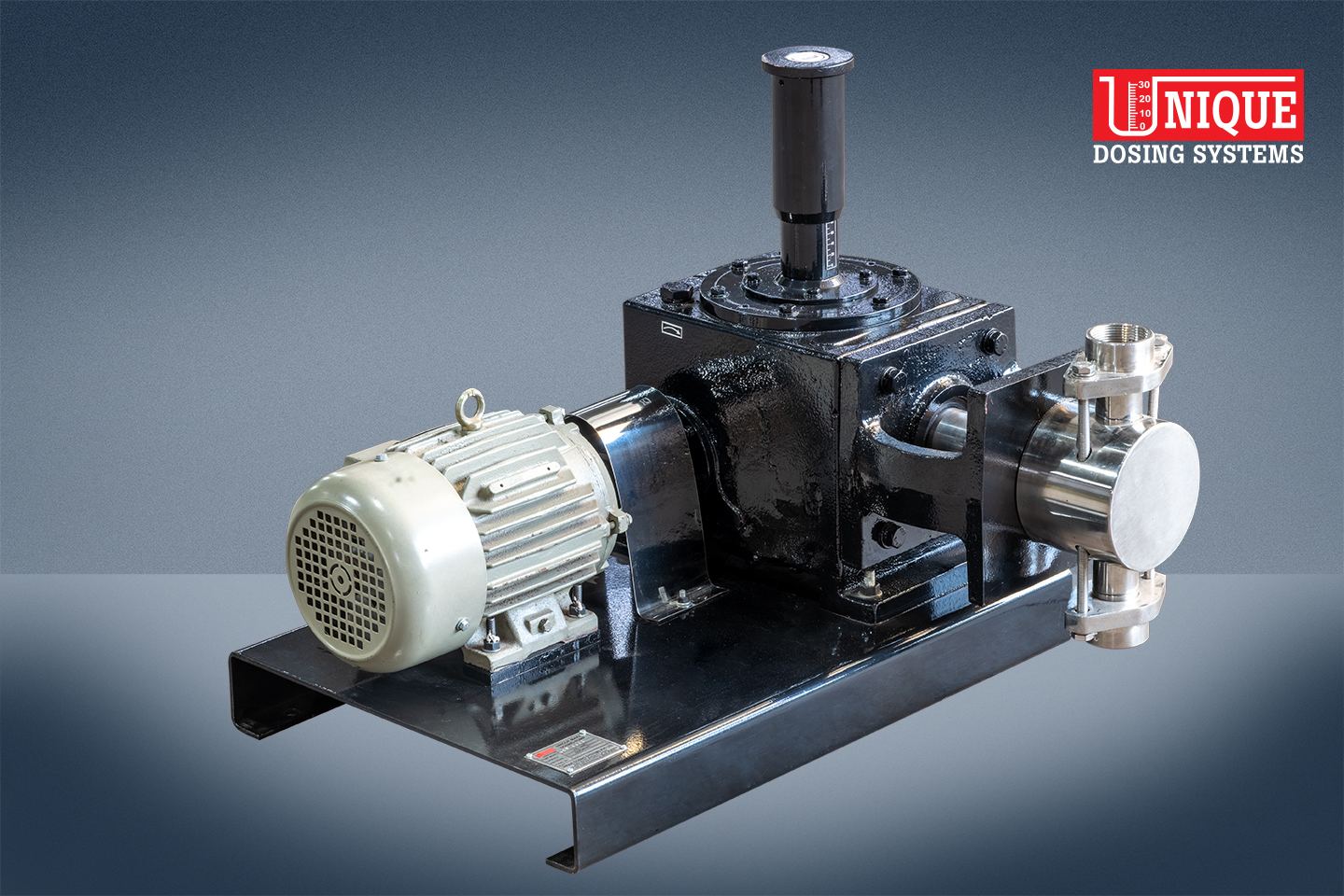

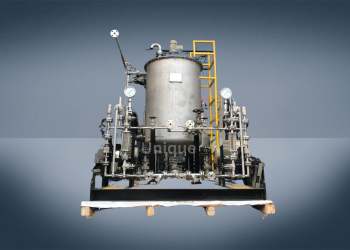

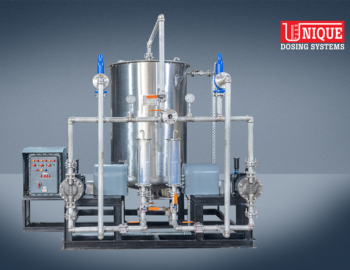

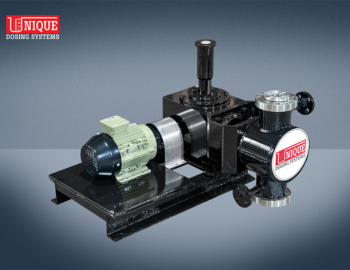

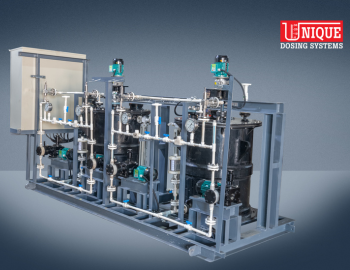

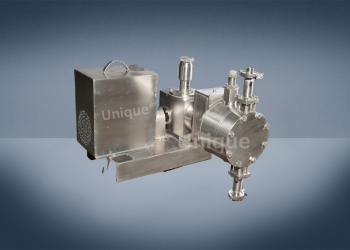

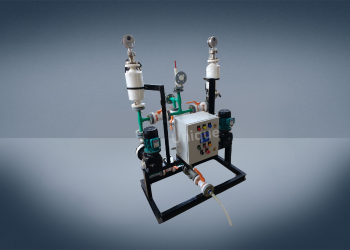

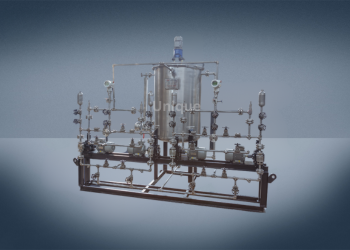

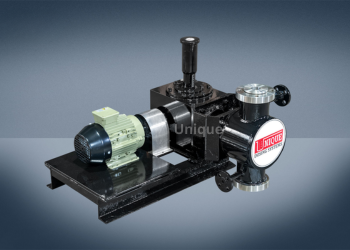

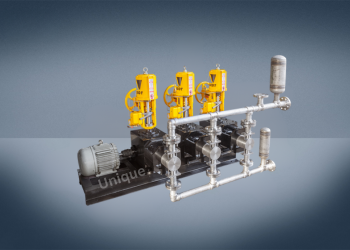

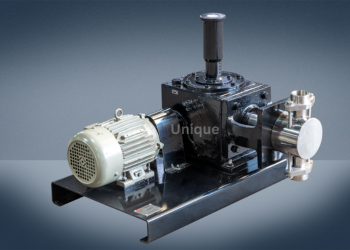

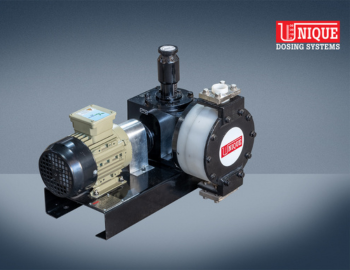

Definition of Dosing pumps are like the bartenders of the industrial world - they deliver precise amounts of liquids, like chemicals or additives, into a system at a controlled rate.

Importance of Dosing Pumps in Various Industries These little champs play a crucial role in industries like water treatment, agriculture, and manufacturing, ensuring that the right amount of stuff gets mixed in at the right time.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters