Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

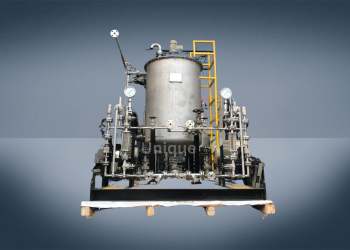

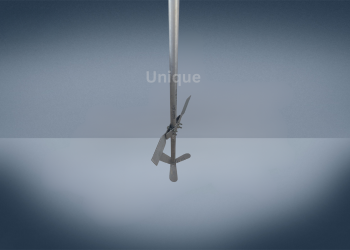

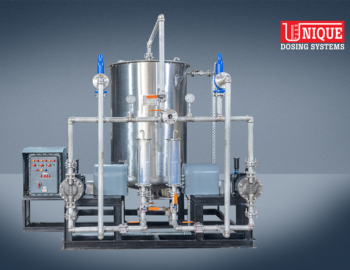

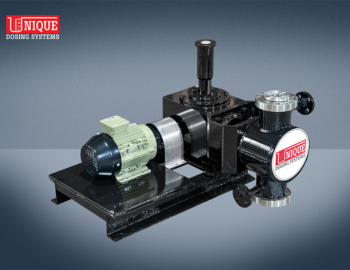

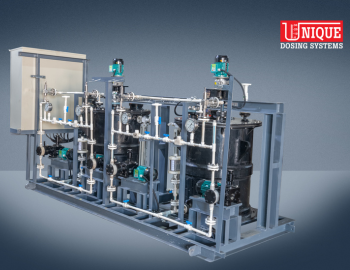

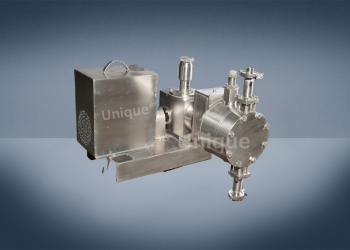

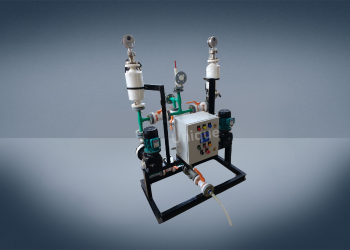

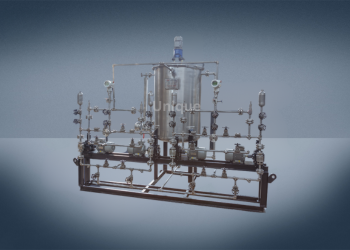

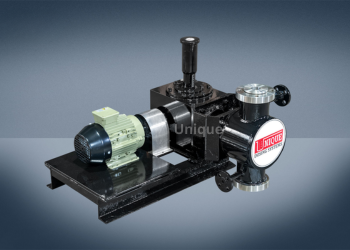

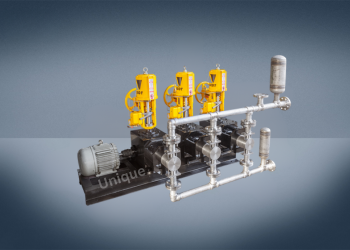

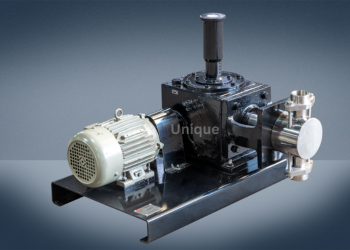

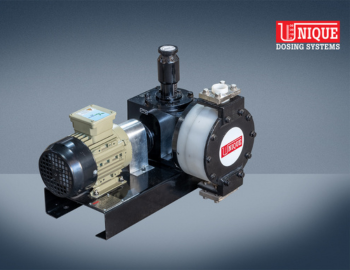

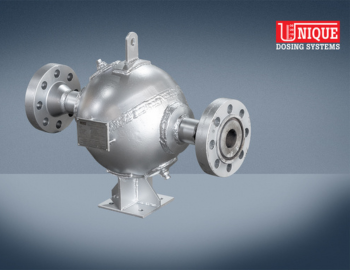

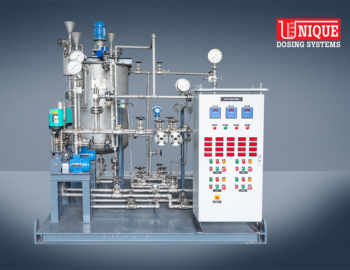

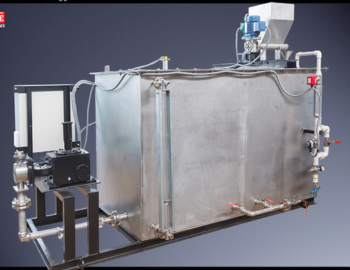

Boiler Chemical Dosing System Boiler Chemical Dosing System Manufacturers has exactly designed single or multiple chemical dosing pumps, result medication single or cube tank, faucets, stirrer( kindler), hitching pipeline and fittings. it's also equipped with colorful instruments like position needles, pressure needles, PRV detectors, position switches and VFD. Our boiler chemical dosing system is designed by our professionals with perfection to confirm low operating cost and provident performance. Designed to perfection, this boiler chemical dosing system ensures effective performance at low operating cost. Further, our guests can mileage this boiler chemical dosing system from us at provident price.

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters