Address

Plot No. - M88, MIDC, Ambad, Nashik - 422010, Maharashtra, India

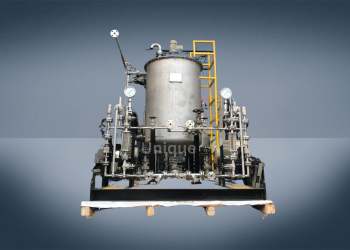

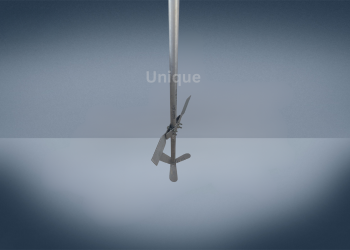

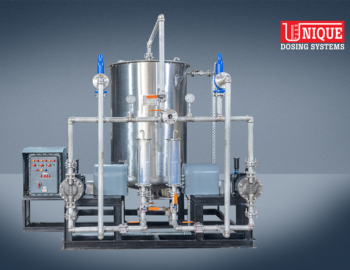

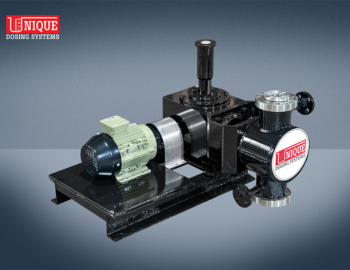

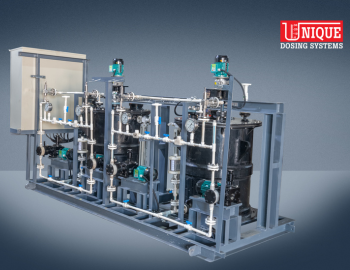

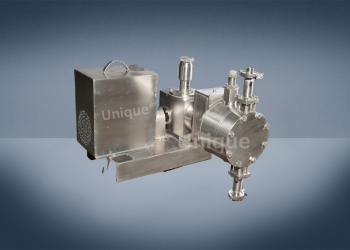

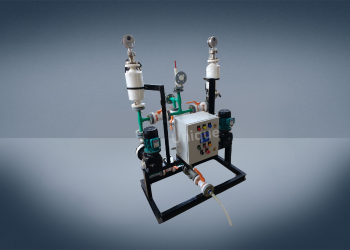

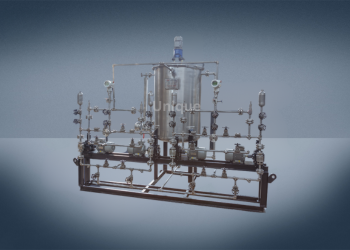

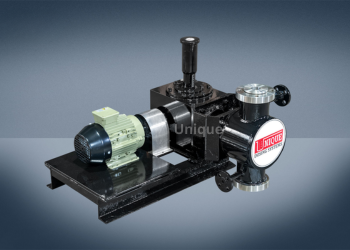

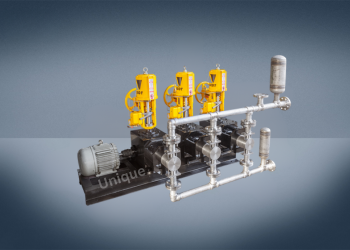

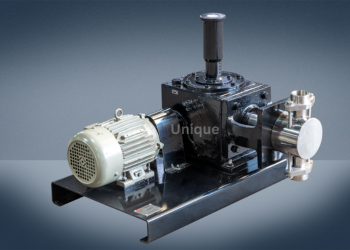

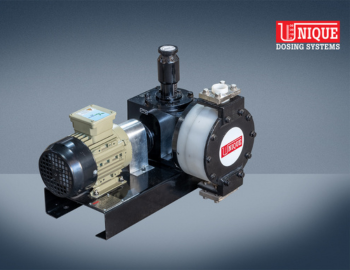

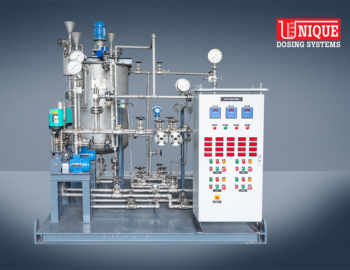

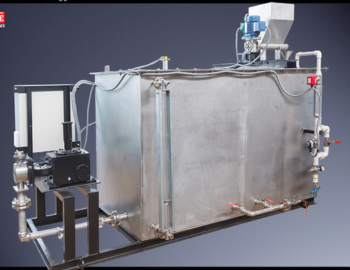

Unique Dosing Systems offers customized Auto Controlled Dosing Pumps which controls the System automatically. Specially, this type of Pump is designed as per User requirements. These Pump dose the liquid smoothly with its universal connection to existing process systems.

Pharmaceutical IndustryChemical Industry

Bring to the table win-win survival strategies to ensure

proactive domination. At the end of the day, going for

ward, a new normal.

+ Country

Satisfied clients

Years experiences

Qualty paramerters